Teamwork gets your food from farm to table!

Lesson plan + STEM activity

This lesson plan is based on the Toronto District School Board’s character theme for January: teamwork. It is a perfect fit for food production where many different things done by many different people have to come together.

The ability to be part of a team is an important skill for students to develop. Successful teamwork at school helps children develop the global competencies, or transferable skills, (the 6 Cs of deep learning) that encourage students to engage actively with their learning and apply their knowledge to real-world situations. Those six qualities (collaboration, citizenship, character/compassion, creativity, critical thinking, communication) also apply to agriculture and its corollary businesses.

In this lesson, we will explore the chain of teams required to get food from farm to table.

Lesson plan

Note: The following content has been written so you can use it easily in your teaching slides.

Curriculum relevance

Transferable skills across the Ontario curriculum:

Critical thinking and problem solving; innovation, creativity and entrepreneurship; collaboration; global citizenship and sustainability; communication; and digital literacy.

Grade 3 Science and Technology

A3. Applications, Connections, and Contributions

A3.1: describe practical applications of science and technology concepts in various occupations, including skilled trades, and how these applications address real-world problems.

Preparing for the lesson:

Students may see teams only as the groups they form at school to do a project or play a sport. But teams can take many forms depending on their purpose and they can change as the team’s goals are met.

You may wonder why agriculture requires teams. After all, doesn’t nature do a lot of the work? It is true that a farmer may not always work with a team and the farmer’s family is often the team for daily operations, such as fixing things or loading software on farm tech. But for large jobs, like harvesting crops, it makes sense to have a group come together. And the farm is only the first step.

LESSON IDEAS

Minds ON!

Did you know?

Astronaut Chris Hadfield, the first Canadian to walk in space and to command the International Space Station, grew up on a corn farm in Ontario.

Colonel Hadfield was part of the family team, along with his brothers and sisters, doing jobs on the farm. He liked school because he knew learning how to learn hard things would help him become an astronaut, where he is a great team member!

For a little fun, watch Colonel Hadfield singing in space on the ISS! Space Oddity (video length is 5:30) or demonstrating how astronauts was their hands in zero-g (1:46)

Discuss: How do you think teamwork is important to being an astronaut?

Today, we are going to do some thinking about how teamwork plays out in areas of our lives that may surprise you!

Sources:

An Astronaut’s Guide to Life ~ Chris Hadfield, pp 4–5

Chris Hadfield: From humble roots to lofty heights | Canadian Space Agency

Lesson content:

When you think of teamwork, you might think of group projects of the sports that you play. But teams can take many forms depending on their purpose and they can change as the team’s goals are met.

Discuss: What are some other examples of teamwork in careers and jobs?

We are going to think about our food and agriculture. You may wonder why agriculture requires teams. After all, doesn’t nature do a lot of the work? It is true that a farmer may not always work with a team and the farmer’s family is often the team for daily operations, such as fixing things or loading software on farm tech. But for large jobs, like harvesting crops, it makes sense to have a group come together. And the farm is only the first step.

Getting food, such as bread, from the field to the table takes many steps. Each step has its own team of workers. What happens along the way requires teams—even teams of machines!

Let’s look at how TEAMWORK is crucial to producing the food we eat!

Teamwork on the farm

It all starts in farmers’ fields, with a crop, such as wheat—seeding, taking care of the crop, and harvesting. Harvesting is a huge job! Look at this farmer harvesting wheat alone. Where does wheat go? (YouTube Short) It takes a long time to harvest a field alone—many hours and sometimes over several days! And during that time, weather could become a risk; if it rains or snows, the grain cannot be cut.

Teamwork can come in all sorts of ways on a farm! Often, during harvest, it takes a crew of people to harvest, collect and transport the grain. This could be multiple family members, neighbours, friends or hired employees. Sometimes, a farmer may bring in a team of custom operators who drive the combines and trucks. Custom operators are hired crews of people that move from farm-to-farm harvesting multiple farmer’s crops. Some farmers, like Daniel Chiappetta will hire a custom operator to harvest their fields.

During harvest, everyone works together as a team. They collaborate to get the job done. They plan their routes and communicate with each other to operate safely as they cut the grain and fill the grain wagon (or cart). They strategize efficient ways to work together and get the work done and collaborate on problem solving any issues that arise during harvest. Farmers and their team will pitch in and help each other with various jobs like opening gates, unhooking wagons, or transporting the machines, trucks and driver operators from field to field. And, there is a team of people behind the scenes that work together to deliver food and supplies to the field, provide childcare for farming families next generation, and maintain any other equipment or infrastructure on the farm. Teamwork makes the operation more efficient!

This short video (3:30) shows how corn is moved from the combine, to a grain wagon, to a truck. Augurs inside a chute move the grain up and out of the combine into the wagon and from the wagon into a trailer pulled by a semi-truck. When the grain is loaded into the truck, it is ready to be taken to a grain bin or silo where it is stored until it is taken to its next stage, when other teams get involved.

Grain Cart – corn on the move from combine to unloading in the semi!

Teamwork at the Mill

Harvested wheat is taken to a mill to be ground into flour. This short video (3:06) shows how grain is ground using machines. How It’s Made Flour The teams at a flour mill collaborate to get the work done. Mill workers include:

- Millers: make sure the mills grind the wheat into the right types of flour; supervise the people operating the mills and other machines

- Junior millers: help the miller; load flour tankers (trucks) that take flour to another destination

- Maintenance workers: keep machines operating

- Lab workers: scientists who make sure the flour is of good quality and has the right characteristics for the type of food it will be made into.

- Administrators: make sure orders are filled and team members are paid.

Teamwork at the Bakery

The next step on the way to your table is the bakery! You may have made bread at home, one or two loaves at a time. At small bakery stores, a small team bakes bread and other food and sells it. To have enough bread to sell in grocery stores, we have huge bakery factories where teams of workers are responsible for different jobs. This video (3:03) shows a small factory. How It’s Made Bread Some factories can make hundreds of loaves at a time. Bakery jobs include:

- Bakers: create recipes; order the amount of ingredients needed; must know what types of flour are required for different products and how to make them, such as bread, rolls, muffins, cookies, cakes

- Bakery labourers: must know about food safety; transport raw materials within the bakery; measure ingredients and add them to the machines; pack finished products into containers for delivery

- Maintenance workers: keep machines operating

- Supervisors: coordinate schedules so every team has the right number of people at each stage

Teamwork at the Store

Once the baked goods—like bread or cookies!—are ready to sell, they are trucked to a store, where another team has the job of making food available to you. Stores must keep track of how much food they sell and how much food they must order to keep shelves stocked. A short video (2:40) shows some of the jobs in a store.

“On the Job with Bob” – Grocery Store Clerk

Grocery store team members include:

- Department managers: responsible for a section of the store, such as baked goods; make sure inventory is tracked and products don’t run out; maintain employee schedules to make sure the department is looked after

- Assistant managers: help the department managers or store manager run the store; train employees and write their performance reports (like report cards!); handle problems that come up

- Stock clerk: put products (stock) on shelves; create special displays; some stock clerks work overnight, unloading delivery trucks and making sure shelves are full and tidy; make sure the stock room has the correct inventory.

Vocabulary

- agriculture – the science or practice of farming

- auger – a tool like a giant screw made of a rod with curved blades that catches material like grain and spins it to the next blade, moving it up, down, or horizontally

- combine – a machine that harvests wheat; it is called a combine harvester—combine for short—because it combines the work of cutting and threshing

- crop – a plant that is grown for food

- grain bin – a large round structure made of metal for storing and drying grains

- grain elevator – a large grain storage structure where grain is weighed (farmers are paid based on grain weight). The grain is dried and monitored until it can be shipped.

- grain wagon – a wagon pulled by a tractor driven beside a combine. The combine loads the grain into the wagon.

- silo – a tall, round structure made of concrete for storing grains and letting them ferment for animal feed

Action!

STEM Activity – Engineer a conveyor belt

Background:

In the videos of moving grain from a combine to a wagon, the device that moves the grain inside the chute is an auger. An auger moves things up, down, or horizontally. It’s like having many hands moving the grain along. Hmm… does that make the augur a team member?!

Farmer Clint answers the question, What is an auger? in this video here! https://www.youtube.com/watch?v=6KxXQSKxTus

An auger is a type of conveyor; to convey means to move. A conveyor is a device that moves something.

Working in a team, use your imagination, team skills, STEM skills, and recycled materials to design a new conveyor to move grains!

Suggested materials:

- Small items to represent grain (lentils or other dried beans, Lego, pebbles)

- Milk or juice cartons, cardboard boxes—cracker boxes, shoe boxes

- Pens, pencils, wood skewers

- Scissors

- Popsicle sticks, tongue depressors, paper towel or toilet tissue rolls

- Tape, glue

- Rulers—a wood ruler with a groove in the centre could inspire ideas

- Paper or plastic cups—yogurt containers, Dixie cups, lids with sides

- Paper—a cash register tape would be ideal! Newspapers, flyers, or used copy paper.

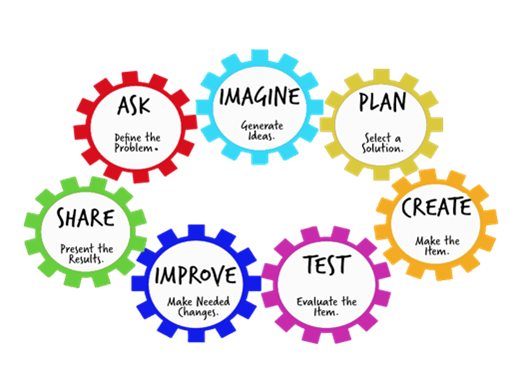

Process: Encourage students to follow the Engineering Design process.

Create: Students will design a conveyor that can transport grain from one point to another. You can use dried corn or beans as your “grain.”

Test & Improve: Students will test their conveyor and make improvements and adjustments.

Share: Students will share what they learned with their classmates about the importance of teamwork on farms, and in creating their own conveyor belts! Ask: What was your biggest takeaway? What would you do differently?

Additional Resources:

- It’s All About Prototypes Video

- 5-minute Makerspace – Simple Conveyor Belt

- Draw with Rob, Tractors in Spaaaace! – Educator Guide. Future Farm Machines, Activity 8 (pg 22) DWR3-Tractor E

Wrap-up:

Tell the story!

Individually or in teams, have students summarize what they’ve learned about the teamwork involved in getting food from farm to table and deliver their summary to another student acting as someone learning about food. After the summary, ask students to identify why the person should find the information important.

Videos included in this lesson

- Colonel Chris Hadfield singing in space on the ISS! Space Oddity

- Where does wheat go? (YouTube Short)

- Ask a Farmer: What is an auger?

- Grain Cart – corn on the move from combine to unloading in the semi!

- How It’s Made Flour

- How It’s Made Bread

- “On the Job with Bob” – Grocery Store Clerk

- Cooperation For Kids | Working Together to Get Things Done

And one more!

This video shows a thorough overview of bread made in a commercial bakery that makes 1.5 million loaves of bread each week.

How Millions Of Bread are Made In A Huge Factory 🍞🏭